Remark:

Cross-corner between front and side sealing

Corrosion mode-II

Remark:

Cross-corner between front and degassing sealing

Corrosion mode-III

Remark:

Tip-effect due to mutual-folding

Corrosion mode-IV

Remark:

Weak spot after Hot-sealing/Folding/Activation/Aging

Corrosion mode-V

Remark:

Front-sealing bar is too near from cell body

The relevant evidence for corrosion---DOE

Remark:

1.Positive electrode contacts with Al layer directly with different “R” value range;

2.Negative electrode contacts with Al layer directly with different “R” value range;

Ni tab点锡静置7天后腐蚀状况统计

Ni tab点锡静置40天后腐蚀状况统计

Ni tab点锡静置28天后腐蚀状况统计

Ni tab点锡静置40天后腐蚀状况统计

Corrosion Mechanism

Comments:

1.Weak points on sealing zone lead to Al layer exposure in electrolyte;

2.Measuring the resistance between Ni tab and Al foil can detect the weak point existence

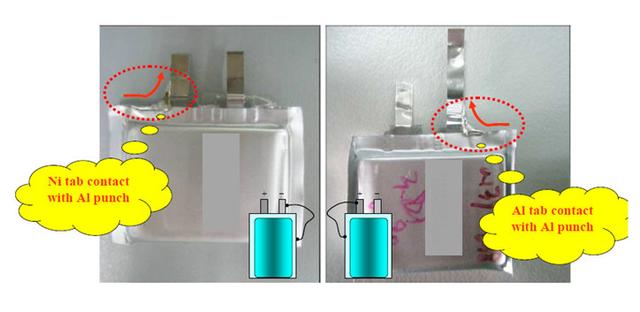

Some potential failure causes-1

Remark:

导电柄间距变异,前封封头凹槽台阶压导电柄-------”R”值变小

Some potential failure causes-2

Remark:

电芯折边PP层折裂,Al层暴露-------”R”值变小

Some potential failure causes-3

Remark:

隔离膜参与前封-------”R”值变小

Some potential failure causes-4

Remark:

电芯折边PP胶粒压迫Al层,Al层断裂,外部水份侵入-------”R”值变小

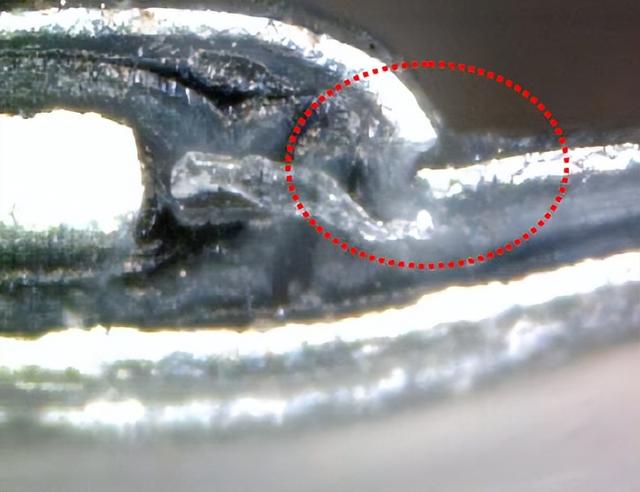

Some potential failure causes-5

Remark:

封头凹槽台阶太锋利,热封后斩断Al层,外部水份侵入-------”R”值变小

Some potential failure causes-6无图

Remark:

极耳毛刺刺破PP层-------”R”值变小

Some potential failure causes-7无图

Remark:

Pack装配焊接PTC或Fuse过程中,折叠Ni tab两者直接发生短路:-------”R”值变小甚至为零

Some potential failure causes-8无图

Remark:

活性材料particle参与热封装:-------”R”值变小

Al tab点锡静置40天后腐蚀状况统计

Al tab和Ni tab都未点锡静置40天后腐蚀状况统计

Remark:

包装铝箔边缘与电芯的正极接通不会发生腐蚀,就像铝壳电池最外面

就是电池的正极,正极在充放电中得电子被还原保护--------不腐蚀

Remark:

软包装电芯的负极和包装铝袋的铝层之间要有足够大的电阻,将是

电芯不发生腐蚀的重要前提。

总结软包装电芯腐蚀现象杜绝须重视以下几个方面:

工序(热封装,弯边,折边)等需重视减少weak point的产生可能性;---PP胶粒形状、大小控制,未封区域宽度控制,减少弯边制具对封边剪切作用,折边减少铝袋尖角效应。“R”值检测是检验“weak point”,避免腐蚀的有效方法。很大一部分腐蚀的case是在客户端使用不当,或者是在装配Pack时没有充分考虑到负极和Al袋直接短接的潜在危害性。